Zhengzhou Manxing Machinery Equipment Co., Ltd.

PRODUCT PARAMETERS

Description

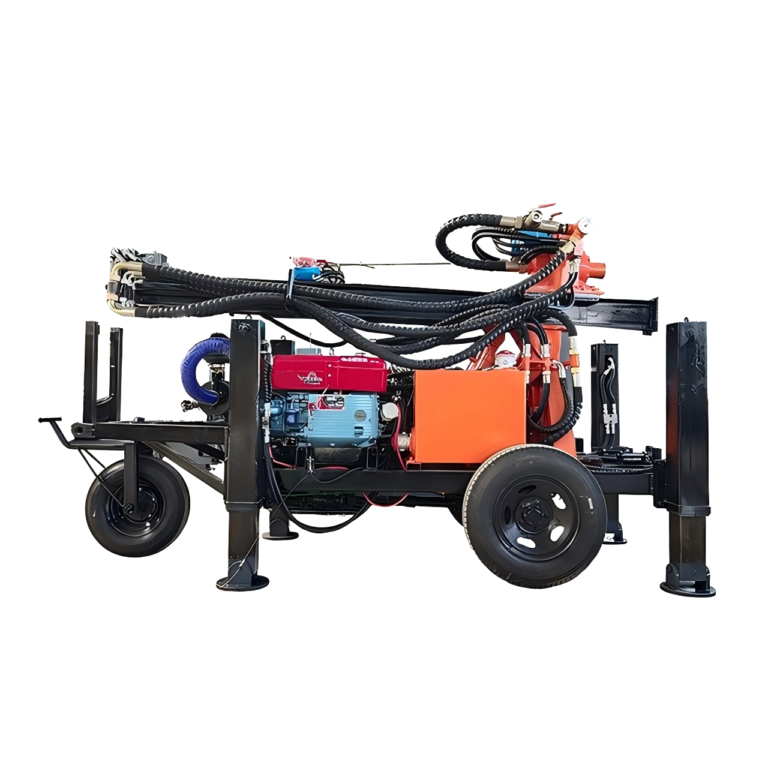

The drilling rig is mounted on a special vehicle chassis and adopts a unique dual-use water and gas design, enabling it to flexibly cope with various complex geological conditions. Whether it is water well construction, geothermal development, geological exploration or agricultural water conservancy project construction, it can accomplish the task with ease. Its excellent performance, reliable quality and convenient operation make it the preferred equipment for many industries.

- Product Features

Vehicle-mounted design, quick turnaround: mounted on a standard truck chassis, it moves quickly and is suitable for frequent turnaround construction needs.

Dual use of water and air, strong adaptability: supports both mud drilling and air drilling processes, suitable for loose soil, gravel and rock layers and other complex geological conditions.

High-efficiency drilling, energy-saving and environmental protection: Equipped with a powerful power system, the drilling speed is fast, and the energy consumption is optimized to reduce the running cost.

Reasonable structure, easy operation: humanized control panel, flexible and convenient operation, suitable for a variety of construction scenarios.

Durable and convenient maintenance: the core components are made of high-strength materials for long service life; the modular design is convenient for maintenance and repair.

2. Application Fields

Agricultural water conservancy: drilling water wells for agricultural irrigation and residential water supply.

Geothermal development: geothermal drilling construction, help clean energy development.

Geological exploration: exploration of mineral resources and construction of test wells.

Foundation engineering: small and medium-sized pile foundation construction and engineering reinforcement work.

3. Product Advantages

High mobility: the vehicle-mounted design enables the equipment to have strong transit capability, significantly shortening the construction preparation time.

Dual process support: water and gas dual-use function improves geologic adaptability and meets a variety of construction needs.

Energy saving and high efficiency: optimized design of power system, high drilling efficiency, low energy consumption and lower running cost.

Economical and durable: the whole machine has stable performance, convenient maintenance, long service life, and high comprehensive price ratio.

Safe and reliable: Equipped with multiple safety protection devices to ensure the safety of construction personnel.

4. Product Parameters

| Truck-Mounted Water Well Drilling Rig | |||

| The weight(T) | 4.7 | Drill pipe diameter(mm) | Φ76 Φ89 |

| The hole diameter(mm) | 140-254 | Drill pipe length(m) | 1.5m 2.0m 3.0m |

| Drilling depth(m) | 200 | Rig lifting force(T) | 13 |

| One-time advance length(m) | 3.3 | Rapid rise speed(m/min) | 20 |

| Walking speed(km/h) | 20-40 | Fast feeding speed(m/min) | 40 |

| Climbing angles(Max.) | 30 | Swing speed(rpm) | 45-65 |

| Equipped capacitor(kw) | 65 | Hoisting force of winch(T) | —- |

| Using air pressure(MPA) | 1.7-2.5 | Swing torque(N.m) | 3400-4700 |

| Air consumption(m³/min) | 17-31 | Dimension(mm) | 4350×1600×2450 |

| The penetration efficiency(m/h) | 10-35 | High leg stroke(m) | 1.4 |

| The engine brand | Quanchai engine | ||

FAQs

- Applications: Designed for drilling water wells in various geological conditions (soft soil, sand, gravel, and hard rock).

- Features:

- Compatible with air compressors or mud pumps for efficient drilling in diverse terrains.

- High mobility with trailer/truck-mounted configurations for remote site access.

- Typical drilling depth: 100–500 meters, adaptable to regional requirements.

- Advantages: Energy-efficient, user-friendly controls, and modular design for easy maintenance.

- Applications: Geological exploration (metal/non-metal mineral surveys), hydrogeological studies, and oil/gas field exploration.

- Features:

- Rope coring technology for precise sample extraction.

- Hydraulic systems for stable operation in challenging environments.

- Drilling diameter: 50–150 mm; depth up to 1,000 meters.

- Advantages: High core recovery rate, low vibration, and compatibility with wireline drilling systems.

3. DTH (Down-the-Hole) Drilling Rig

- Applications: Ideal for hard rock formations in mining, quarrying, and geothermal projects.

- Features:

- Pneumatic hammer drills for rapid penetration.

- Adjustable air pressure (1.7–3.5 MPa) and customizable hole diameters (102–114 mm).

- Supports depths up to 300 meters.

- Advantages: Reduced deviation, high drilling speed, and minimal wear on tools.

4. HDD (Horizontal Directional Drilling) Rig

- Applications: Underground pipeline/utility installation without trenching, suitable for urban areas and river crossings.

- Features:

- GPS-guided steering systems for precision.

- Torque capacity: 10,000–30,000 Nm; pullback force up to 200 tons.

- Drilling length: 100–2,000 meters.

- Advantages: Environmentally friendly, minimal surface disruption, and adaptable to varying soil types.

5. Excavator Mounted Drilling Rig

- Applications:

Mining and Quarry Drilling:Efficient for blast hole drilling in open-pit mines, quarries, and aggregate extraction sites.

Slope Stabilization and Anchoring:Ideal for drilling anchor holes on slopes, embankments, and landslide-prone areas to install rock bolts and soil nails.

Foundation and Piling Work:Used for drilling foundation holes in urban construction, bridges, retaining walls, and infrastructure projects.

- Feature:Easily converts your excavator into a powerful and flexible drilling rig for rock, soil, and foundation applications.

Key Selling Points:

Compliance: Meets international standards (ISO, CE) and adapts to local regulations (e.g., EU VAT, environmental policies).

Customization: Tailored configurations (e.g., crawler/wheel-mounted) to meet project-specific needs .

After-Sales Support: 24/7 technical assistance, regional service centers, and extended warranty options .

We offer high-efficiency logistics solutions and secure delivery of heavy-duty drilling equipment. Here’s how we handle shipments:

Support EXW, FOB, CIF, DDP, etc., tailored to your needs.

Transportation Options

Sea Freight: Cost-effective for large machines (e.g., rigs exceeding 10 tons). Suitable for long-distance international shipments. Delivery time: 25–45 days1.

Air Freight: Fast-track delivery for urgent orders or spare parts. Delivery time: 3–10 days1.

Land Freight: Ideal for regional deliveries (e.g., within Asia or Europe). Includes truck or rail transport.

Multimodal Solutions: Combined sea/air/land transport for optimized cost and efficiency.

Packaging & Safety

Heavy machinery is securely packed with steel frames, weatherproof wooden crates, and anti-rust treatments1.

Fragile components (e.g., hydraulic systems) are individually padded and labeled.

Customs & Documentation

We provide full export documentation (commercial invoice, packing list, COO, etc.) and assist with customs clearance globally.

Delivery Assurance

Real-time tracking: Monitor shipments via our logistics platform.

Insurance coverage: Optional all-risk insurance for high-value equipment.

Flexible Trade Terms

Yes, mechanical equipment can be fully customized to meet your specific requirements. Here’s a structured overview:

1. Customization Scope

- Functional Adaptations: Tailored to your operational needs (e.g., power output, precision, automation level) .

- Design Modifications: Adjustments in size, material, and ergonomic layout to fit your workspace.

- Integration Capabilities: Compatibility with existing systems (e.g., IoT sensors, production line interfaces).

2. Key Benefits

- Optimized Efficiency: Custom designs align with your workflow, reducing downtime and energy waste.

- Cost Savings: Eliminate unnecessary features while prioritizing critical functionalities.

- Competitive Edge: Unique equipment enhances product quality and differentiation in your market.

3. Process Overview

- Consultation: Detailed analysis of your needs and operational environment.

- Prototyping: 3D modeling and testing to validate design feasibility.

- Production: Advanced manufacturing techniques (e.g., CNC machining, laser cutting) ensure precision.

- Post-Sale Support: Installation, training, and maintenance services included.

4. Industries Served

- Heavy machinery, automotive, aerospace, and precision engineering sectors.

For a tailored solution, collaborate with a specialized manufacturer to discuss technical specifications and project timelines. Let us know your requirements—we’ll handle the rest!