Zhengzhou Manxing Machinery Equipment Co., Ltd.

PRODUCT PARAMETERS

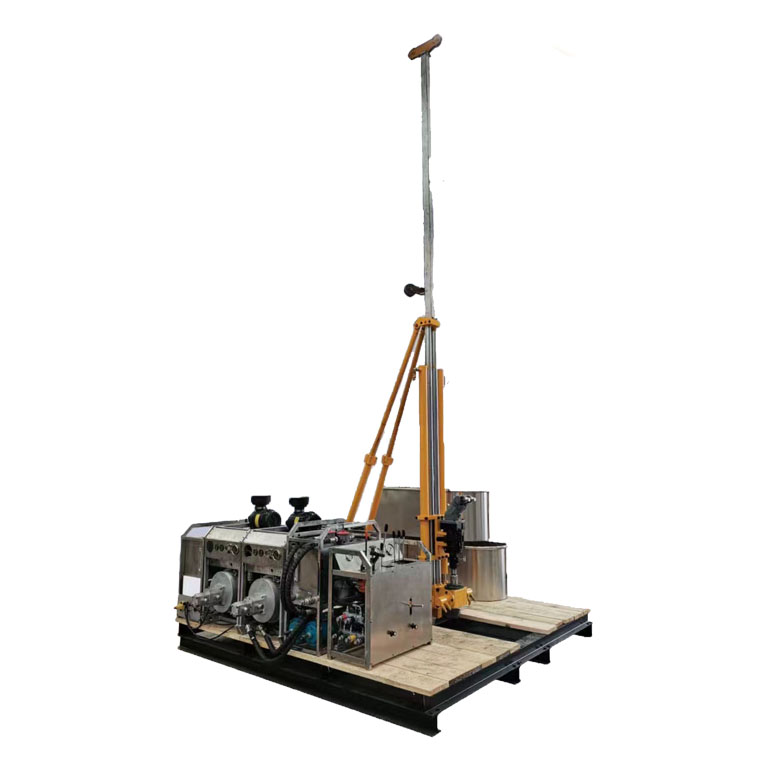

Description

Product Features

- Powerful power system

Power Configuration: Equipped with high power turbocharged diesel engine, providing continuous and stable strong power output.

Hydraulic drive: It adopts full hydraulic drive, with high transmission efficiency and stable torque output, suitable for deep hard rock drilling. - High-efficiency drilling performance

Maximum drilling depth: 1500 meters

Maximum drilling diameter: 400mm

Power head torque: up to 18000N-m, easy to deal with hard rock drilling.

Three speeds adjustable, suitable for a variety of strata (rock layer, mud layer, sand layer) - Hydraulic control system

Independent hydraulic oil pump: parallel gear box design, more reasonable power distribution, low maintenance cost.

Hydraulic cooling system: efficient heat dissipation device prevents hydraulic oil from overheating, suitable for long time high load operation.

Automatic hydraulic control: lifting, rotating, advancing, clamping and other actions are all controlled by hydraulic pressure. - Drill tower and lifting system

Hydraulic lifting tower: double cylinders lifting and lowering, with stronger stability and safety.

Maximum lifting capacity: up to 25 tons.

The height of the drilling tower is adjustable to meet different drilling depth requirements. - Undercarriage and traveling system

Crawler chassis: Adopting heavy-duty excavator crawler chassis with strong off-road performance.

Vibration-damping structure: suitable for mountainous areas, muddy areas and other complex environments.

Strong load-bearing capacity: can work on hard ground and reduce ground damage. - Safety and maintenance design

Hydraulic oil pipe protection sleeve: each hydraulic oil pipe is equipped with a thickened protection sleeve to prolong its service life.

Centralized control panel: easy to control and maintain

Automatic hydraulic legs: easy to quickly adjust the level of the equipment to improve operational safety.

Product Advantages

Ultra-deep drilling capacity: drilling depth up to 1500 meters, to meet the needs of deep mineral exploration

Strong power: high-power turbocharged diesel engine, stable power output.

High-efficiency hydraulic system: independent oil pump design, reasonable power distribution and low maintenance cost.

Stable and durable: heavy-duty crawler chassis + hydraulic outriggers, suitable for complex terrain operations.

Safe and reliable: hydraulic pipe protection sleeve + automatic outriggers, guaranteeing the safety of operation.

Strong adaptability: suitable for a variety of complex geological environments.

Applicable fields

Mineral resources exploration: metal mines, non-metal mines, coal mines, etc.

Hydrogeological survey: deep water wells, geothermal wells drilling

Geological research: deep core sampling and geological analysis

Engineering exploration: highway, railroad, bridge and other basic engineering survey

FAQs

- Applications: Designed for drilling water wells in various geological conditions (soft soil, sand, gravel, and hard rock).

- Features:

- Compatible with air compressors or mud pumps for efficient drilling in diverse terrains.

- High mobility with trailer/truck-mounted configurations for remote site access.

- Typical drilling depth: 100–500 meters, adaptable to regional requirements.

- Advantages: Energy-efficient, user-friendly controls, and modular design for easy maintenance.

- Applications: Geological exploration (metal/non-metal mineral surveys), hydrogeological studies, and oil/gas field exploration.

- Features:

- Rope coring technology for precise sample extraction.

- Hydraulic systems for stable operation in challenging environments.

- Drilling diameter: 50–150 mm; depth up to 1,000 meters.

- Advantages: High core recovery rate, low vibration, and compatibility with wireline drilling systems.

3. DTH (Down-the-Hole) Drilling Rig

- Applications: Ideal for hard rock formations in mining, quarrying, and geothermal projects.

- Features:

- Pneumatic hammer drills for rapid penetration.

- Adjustable air pressure (1.7–3.5 MPa) and customizable hole diameters (102–114 mm).

- Supports depths up to 300 meters.

- Advantages: Reduced deviation, high drilling speed, and minimal wear on tools.

4. HDD (Horizontal Directional Drilling) Rig

- Applications: Underground pipeline/utility installation without trenching, suitable for urban areas and river crossings.

- Features:

- GPS-guided steering systems for precision.

- Torque capacity: 10,000–30,000 Nm; pullback force up to 200 tons.

- Drilling length: 100–2,000 meters.

- Advantages: Environmentally friendly, minimal surface disruption, and adaptable to varying soil types.

5. Excavator Mounted Drilling Rig

- Applications:

Mining and Quarry Drilling:Efficient for blast hole drilling in open-pit mines, quarries, and aggregate extraction sites.

Slope Stabilization and Anchoring:Ideal for drilling anchor holes on slopes, embankments, and landslide-prone areas to install rock bolts and soil nails.

Foundation and Piling Work:Used for drilling foundation holes in urban construction, bridges, retaining walls, and infrastructure projects.

- Feature:Easily converts your excavator into a powerful and flexible drilling rig for rock, soil, and foundation applications.

Key Selling Points:

Compliance: Meets international standards (ISO, CE) and adapts to local regulations (e.g., EU VAT, environmental policies).

Customization: Tailored configurations (e.g., crawler/wheel-mounted) to meet project-specific needs .

After-Sales Support: 24/7 technical assistance, regional service centers, and extended warranty options .

We offer high-efficiency logistics solutions and secure delivery of heavy-duty drilling equipment. Here’s how we handle shipments:

Support EXW, FOB, CIF, DDP, etc., tailored to your needs.

Transportation Options

Sea Freight: Cost-effective for large machines (e.g., rigs exceeding 10 tons). Suitable for long-distance international shipments. Delivery time: 25–45 days1.

Air Freight: Fast-track delivery for urgent orders or spare parts. Delivery time: 3–10 days1.

Land Freight: Ideal for regional deliveries (e.g., within Asia or Europe). Includes truck or rail transport.

Multimodal Solutions: Combined sea/air/land transport for optimized cost and efficiency.

Packaging & Safety

Heavy machinery is securely packed with steel frames, weatherproof wooden crates, and anti-rust treatments1.

Fragile components (e.g., hydraulic systems) are individually padded and labeled.

Customs & Documentation

We provide full export documentation (commercial invoice, packing list, COO, etc.) and assist with customs clearance globally.

Delivery Assurance

Real-time tracking: Monitor shipments via our logistics platform.

Insurance coverage: Optional all-risk insurance for high-value equipment.

Flexible Trade Terms

Yes, mechanical equipment can be fully customized to meet your specific requirements. Here’s a structured overview:

1. Customization Scope

- Functional Adaptations: Tailored to your operational needs (e.g., power output, precision, automation level) .

- Design Modifications: Adjustments in size, material, and ergonomic layout to fit your workspace.

- Integration Capabilities: Compatibility with existing systems (e.g., IoT sensors, production line interfaces).

2. Key Benefits

- Optimized Efficiency: Custom designs align with your workflow, reducing downtime and energy waste.

- Cost Savings: Eliminate unnecessary features while prioritizing critical functionalities.

- Competitive Edge: Unique equipment enhances product quality and differentiation in your market.

3. Process Overview

- Consultation: Detailed analysis of your needs and operational environment.

- Prototyping: 3D modeling and testing to validate design feasibility.

- Production: Advanced manufacturing techniques (e.g., CNC machining, laser cutting) ensure precision.

- Post-Sale Support: Installation, training, and maintenance services included.

4. Industries Served

- Heavy machinery, automotive, aerospace, and precision engineering sectors.

For a tailored solution, collaborate with a specialized manufacturer to discuss technical specifications and project timelines. Let us know your requirements—we’ll handle the rest!